Privacy statement: Your privacy is very important to Us. Our company promises not to disclose your personal information to any external company with out your explicit permission.

Model No.: JL-SML02

Brand: JINLAN

Place Of Origin: China

EV Motor Stator: Customized Cycle Time

Servo Nozzle Adjustment: Data Traceability System

Packaging: PLYWOOD PACKING

Productivity: 20000-30000pcs per year

Transportation: Ocean,Land,Air

Place of Origin: SUZHOU,CHINA

Supply Ability: 20 SETS PER YEAR

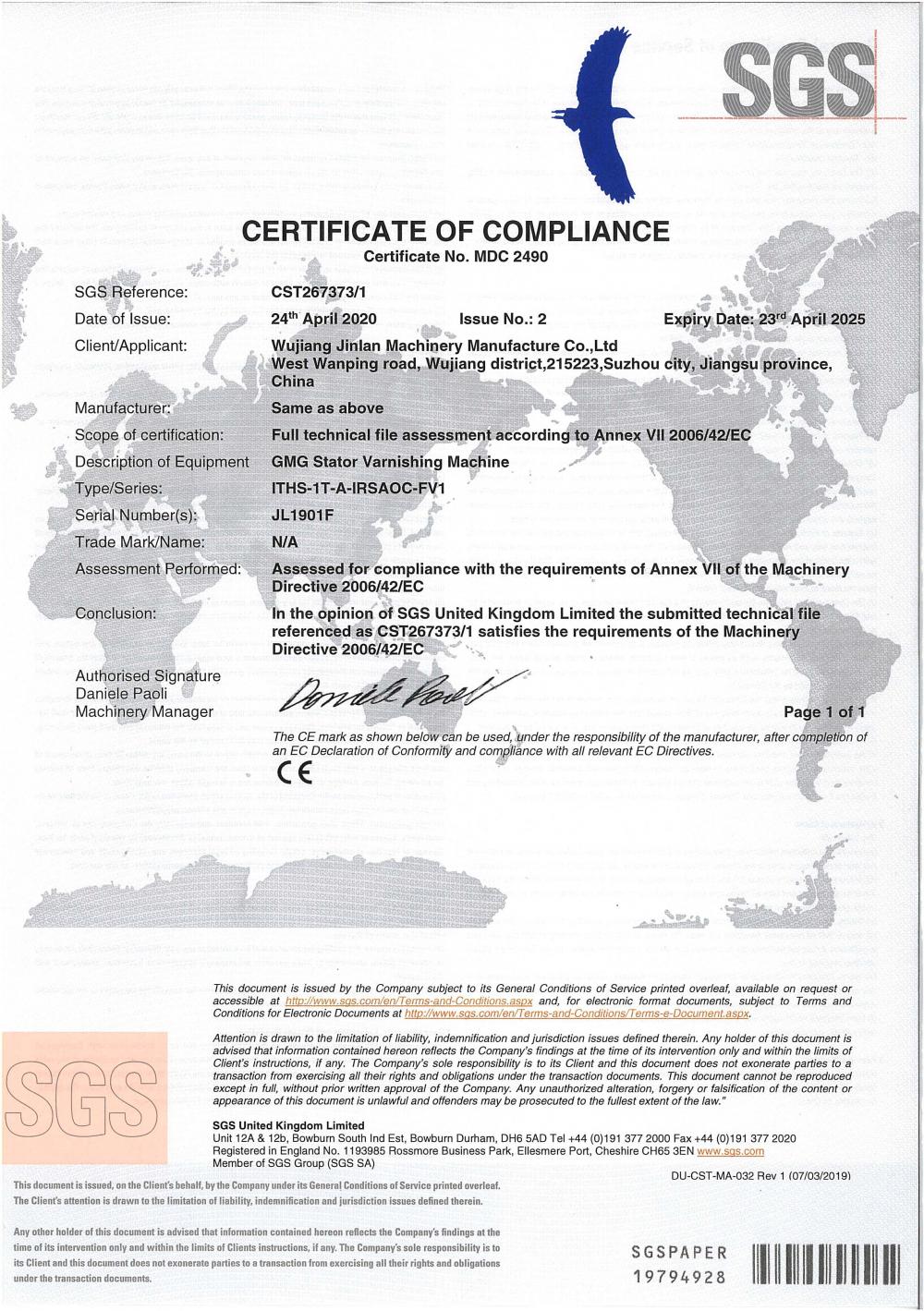

Certificate: ISO 9001;CE certificate

HS Code: 8419899090

Port: SHANGHAI

Payment Type: T/T

Incoterm: FOB,EXW

Product Introduction

Used for varnishing treatment the stator copper coils, widely applied for different models. It boasts of precise resin quantity control and automatic nozzle positioning. The production line is composed of resin mixing system, preheating oven, servo trickling system, gelling, curing, and cooling conveyor, HMI, etc.

Product Pictures

Product Features

automatic nozzle positioning;

flexible product model changeover;

temperature zone control;

data traceability system;

varnishi quantitative control

Process Parameters

| Product models | Flat copper wire/round copper wire | / |

| load/unload system | manual/robot | Can be connected with the production lines both in front and at the back |

| Product clamping | Inner supporting/external clamping | To be designed according to the product models |

| Output accuracy | 1%-10% | Multiple configurations, to be designed based on customer's technical specifications |

| Single machine cycle time | ≥45s | Depending on product model |

| Varnish models | Single component/two- component | |

| Varnish temp control | 10-50℃ | Varnish temp will be protected in heating and cooling working system |

| Flow rate monitoring | pressure/flow rate monitor | Anti-clogging/fail-safe monitor |

JINLAN serves the automobile industry with three key technologies, trickling impregnation, automatic assembly, and professional test. The main products which we serve the industry with include Stator Varnishing Machine, Rotor Assembly Line,Stator Test Machine,Eps Power Head Test Line, Charge Cable Assembly line, EPS Power Head Test Line and Car Seat Assembly Line. Our products are widely used in industries of generator, Starter , Car Seat , Steering System and New Energy Vehicle.

Product Categories : New Energy Vehicle > EV Drive Motor Stator Varnishing Machine

Privacy statement: Your privacy is very important to Us. Our company promises not to disclose your personal information to any external company with out your explicit permission.

Fill in more information so that we can get in touch with you faster

Privacy statement: Your privacy is very important to Us. Our company promises not to disclose your personal information to any external company with out your explicit permission.