Privacy statement: Your privacy is very important to Us. Our company promises not to disclose your personal information to any external company with out your explicit permission.

Model No.: JL-MSP01

Brand: JINLAN

Place Of Origin: China

Automatic Leadwire Cutting: Automatic Coating

Packaging: PLYWOOD PACKING

Productivity: 20000-40000PCS PER YEAR

Transportation: Ocean,Land,Air

Place of Origin: Suzhou China

Supply Ability: 20 SETS PER YEAR

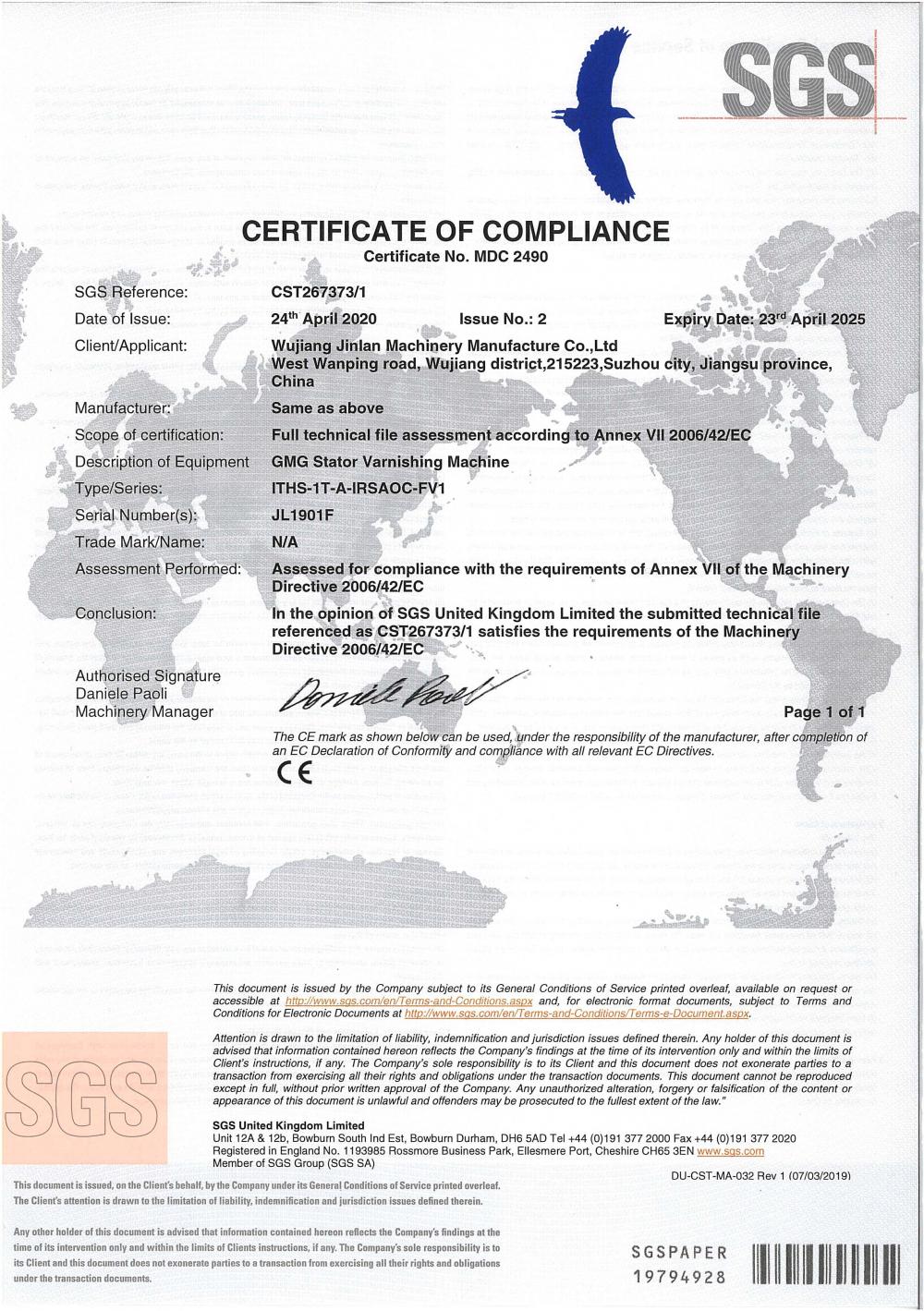

Certificate: ISO 9001;CE certificate

Port: SHANGHAI

Payment Type: T/T

Incoterm: FOB,DDP,EXW

Product Introduction

Adopted for automatic production of the generator stator with high efficiency. This equipment provides you complete stator solution including high-frequency leadwire burning, auto wire brushing, lead wire cutting, 2-station tin coating and visual check with competitive high precision and smart quality control.

Product Pictures

JINLAN has established cooperative relations with over 10 global top automotive parts manufacturers since its foundation in 2007 based on its independent research resources. And our products have been spread to most Europan countries. All these smart solutions are widely adopted for automatic manufacturing of Generator Stator Series;Generator Rotor Series; Generator Brushholder;Starter; Steering System; New Energy Vehicle; Automotive seat and Car Motor etc.

Product Categories : Generator Stator Series > Stator Finishing Machine

The key solutions we can offer include: EV drive motor stator varnishing line, stator epoxy coating machine,stator lacing machine,EV drive motor general assembly line,EV charge cable assembly line,rotor assembly line, stator test line, stator varnishing machine, electrical pump assembly line,EPS power head test line,car seat general assembly line,rotor dipping line,brushholder assembly line,etc.

Privacy statement: Your privacy is very important to Us. Our company promises not to disclose your personal information to any external company with out your explicit permission.

Fill in more information so that we can get in touch with you faster

Privacy statement: Your privacy is very important to Us. Our company promises not to disclose your personal information to any external company with out your explicit permission.